|

|

|

|

| |

As an external gear coated with special rubber and an internal gear made of MC Nylon, Teflon, PP, or PE are used, As an external gear coated with special rubber and an internal gear made of MC Nylon, Teflon, PP, or PE are used,

the gears donЁЏt easily wear out so that it will last longer.

|

| |

No noise and vibration when the shaft rotates with high speed. No noise and vibration when the shaft rotates with high speed.

|

| |

Little space is required for installation and it is easy to be moved as motor and the pump are directly connected. Little space is required for installation and it is easy to be moved as motor and the pump are directly connected.

|

| |

Wide range of fluids from the low viscous liquid such as water to the high viscous liquid can be transferred with high pressure. Wide range of fluids from the low viscous liquid such as water to the high viscous liquid can be transferred with high pressure.

|

| |

Chemicals containing sludge and mixture with sands can be also transferred with high speed. Chemicals containing sludge and mixture with sands can be also transferred with high speed.

|

| |

The mechanical seals can be mounted in pair. The mechanical seals can be mounted in pair.

|

When making it as a multistage pump, the liquid containing much sludge can be transferred with constant pressure and When making it as a multistage pump, the liquid containing much sludge can be transferred with constant pressure and

flow rate for a long period.

| |

| |

|

|

| |

Inviscid liquid: water, seawater, water supply in a high-rise, high pressure cleaning machine, fountain, golf course, Inviscid liquid: water, seawater, water supply in a high-rise, high pressure cleaning machine, fountain, golf course,

sprinkler, crop spraying, filter press dehydration, etc.

|

| |

Viscous liquid: lubricant, gear fluid, hydraulic oil, bunker fuel oil C, waste oil, cutting oil, grease, paint, varnish, sealant, Viscous liquid: lubricant, gear fluid, hydraulic oil, bunker fuel oil C, waste oil, cutting oil, grease, paint, varnish, sealant,

glue, etc.

|

| |

Oil: petroleum, gasoline, light oil, thinner, solvent, toluene, alcohol, benzol, acetone, methanol, rolling oil, etc. Oil: petroleum, gasoline, light oil, thinner, solvent, toluene, alcohol, benzol, acetone, methanol, rolling oil, etc.

|

| |

Chemical: hydrochloric acid, sulfuric acid, nitric acid, acetic acid, phosphoric acid, chloric acid, sodium hydroxide, Chemical: hydrochloric acid, sulfuric acid, nitric acid, acetic acid, phosphoric acid, chloric acid, sodium hydroxide,

ferrous chloride, ferric chloride, ferrous sulfate, cupric sulfate, copper chloride, etc.

|

Food: pastes, soy sauce, cooking oil, sesame oil, honey, curry sauces, cream, mayonnaise, ketchup, tofu, fruit juices, Food: pastes, soy sauce, cooking oil, sesame oil, honey, curry sauces, cream, mayonnaise, ketchup, tofu, fruit juices,

beer, etc.

| |

| |

|

|

| |

|

| |

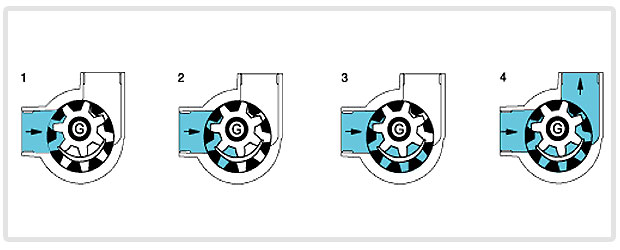

Liquid enters the suction port between the rotor (large exterior gear) and idler (small interior gear) teeth. Liquid enters the suction port between the rotor (large exterior gear) and idler (small interior gear) teeth.

|

| |

Liquid travels through the pump between the teeth of the "gear-within-a-gear" principle. The crescent shape divides the liquid Liquid travels through the pump between the teeth of the "gear-within-a-gear" principle. The crescent shape divides the liquid

and acts as a seal between the suction and discharge ports.

|

| |

The pump head is now nearly flooded, just prior to forcing the liquid out of the discharge port.? Intermeshing gears of the idler The pump head is now nearly flooded, just prior to forcing the liquid out of the discharge port.? Intermeshing gears of the idler

and rotor form locked pockets for the liquid which assures volume control.

|

| |

Rotor and idler teeth mesh completely to form a seal equidistant from the discharge and suction ports. This seal forces the Rotor and idler teeth mesh completely to form a seal equidistant from the discharge and suction ports. This seal forces the

liquid out of the discharge port.

| |

| |

|

|

| |

| MODEL |

HP |

PRESSURE

ЇИ/ЇВ |

PORT SIZE

|

FLOW RATE (l/m) |

cc/Rev |

4P

|

6P |

8P |

| 60Hz |

50Hz |

60Hz |

50Hz |

60Hz |

50Hz |

| 4P |

6P |

1750(RPM) |

1450(RPM) |

1120(RPM) |

950(RPM) |

830(RPM) |

700(RPM) |

| DS-G20W |

1 |

1/2 |

10 |

20A PT |

37 |

31 |

24 |

20 |

18 |

15 |

21.4 |

| DS-G25SW |

2 |

1 |

15 |

25A PT |

86 |

71 |

55 |

47 |

40 |

34 |

49.1 |

| DS-G32W |

2 |

2 |

25 |

32A PT |

125 |

103 |

80 |

68 |

59 |

50 |

71.4 |

| DS-G40SW |

3 |

3 |

30 |

40A PT |

234 |

194 |

150 |

127 |

111 |

93 |

133.9 |

| DS-G50SW |

5 |

5 |

30 |

50A PT |

328 |

271 |

210 |

178 |

155 |

131 |

187.5 |

| DS-G65SW |

|

7.5 |

30 |

65A PT |

625 |

518 |

400 |

340 |

296 |

250 |

357.1 |

| DS-G80SW |

|

7.5 |

30 |

65A Flange |

859 |

712 |

550 |

466 |

408 |

344 |

491.0 |

| DS-G100W |

|

10 |

30 |

80A Flange |

1172 |

970 |

750 |

636 |

555 |

469 |

669.6 |

| DS-G100SW |

|

15 |

30 |

100A Flange |

1875 |

1554 |

1200 |

1018 |

890 |

750 |

1071.4 |

| DS-G120SW |

|

20 |

30 |

125A Flange |

2500 |

2071 |

1600 |

1357 |

1186 |

1000 |

1428.5 |

| DS-G150SW |

|

|

30 |

150A Flange |

5000 |

4142 |

3200 |

2714 |

2372 |

2000 |

2857.1 | |

| | |

|