|

| |

|

|

|

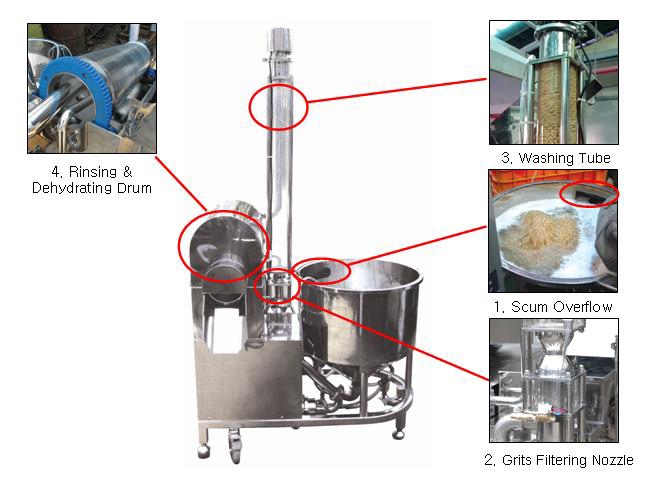

| Its optimum structure allows little space for the system, and it reduces the time for washing cereal crops by the sequential feeding & discharging of the materials. As cereal crops are washed by abrasive method in the tube where water is whirling, the nutrients in the crops are not destroyed during the washing. The rinsing & dehydrating drum which is optional maximizes the convenience of the system. |

| |

|

|

4-Step Washing Process

|

|

1. Scum Overflow – The scum on the water that is boosted by a pump is drained out through

the hopper overflow. |

2. Grits Filtering Nozzle – Relatively heavier grits are filtered by means of specific gravity and

sink at the bottom of the tube through the filtering nozzle. |

|

3. Washing Tube – Cereal crops are washed by abrasive method in the washing tube where

water is whirling. |

|

4. Rinsing & Dehydrating Drum – The crops are rinsed and dehydrated passing through the

revolving drum | |

|

| Structure of Washing Module (Patent No.10-0905064) |

|

Advantages of Cereals Washing System

|

It reduces greatly the washing time compared to traditional washing method. It reduces greatly the washing time compared to traditional washing method. |

It is convenient for everyone to use as it is easy for installation, operation, and maintenance. It is convenient for everyone to use as it is easy for installation, operation, and maintenance. |

The nutrients in cereal crops are not destroyed due to the abrasive washing method. The nutrients in cereal crops are not destroyed due to the abrasive washing method. |

Little space is required for system installation due to its optimum structure with compact size. Little space is required for system installation due to its optimum structure with compact size. | |

|

|

|

Restaurants, food suppliers, institutional food services, military food services, etc. Restaurants, food suppliers, institutional food services, military food services, etc. |

Food processing facilities for rice, soybean, tofu, and so on. Food processing facilities for rice, soybean, tofu, and so on. |

Cereal beverage processing facilities, grain wine facilities, etc. Cereal beverage processing facilities, grain wine facilities, etc. | |

| |

|

|

|